The login window appear first when you trying to log in to the PRODUCTION module. Enter valid user name and password to login as shown below.

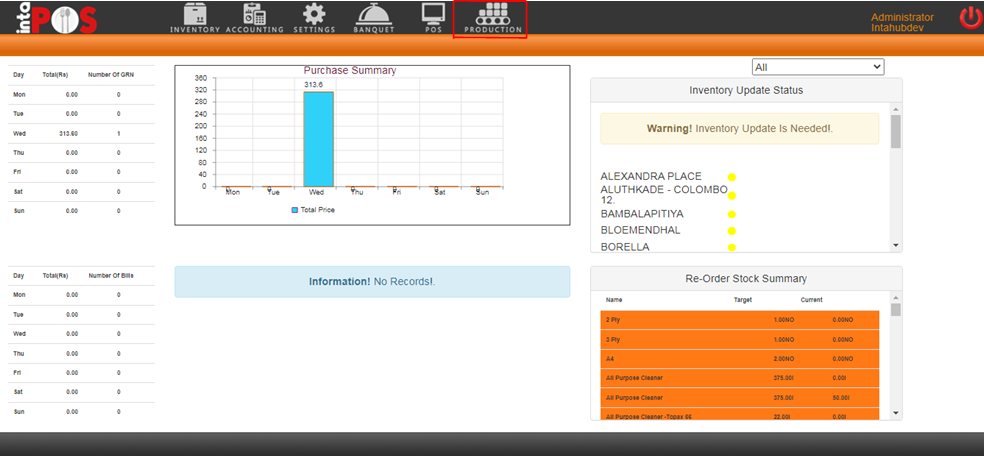

After logging in to the system by using valid user name and password, this main window will appear. This is shown below. You have the option of using the Production module on this main dashboard. As well as this window provides you the option of logging out, when you need to log out from the system.

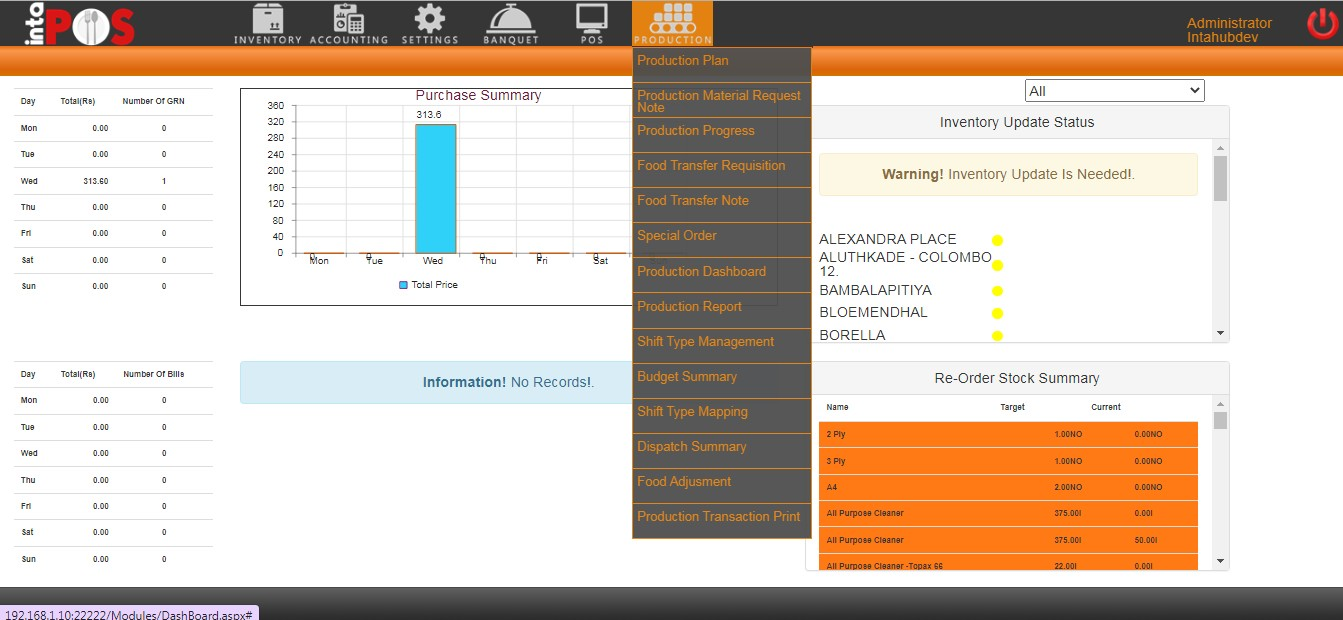

The following things are contained in our Production module

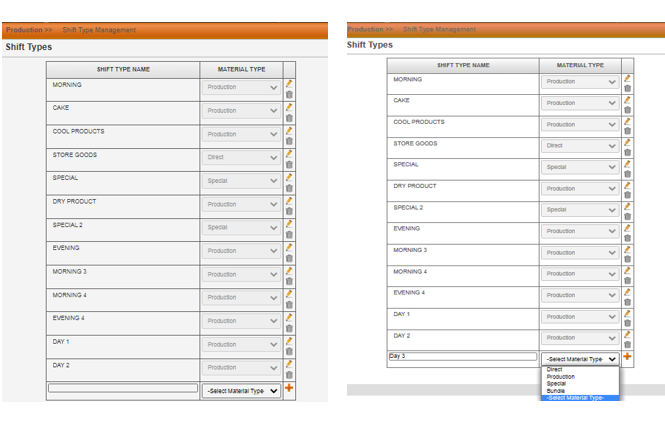

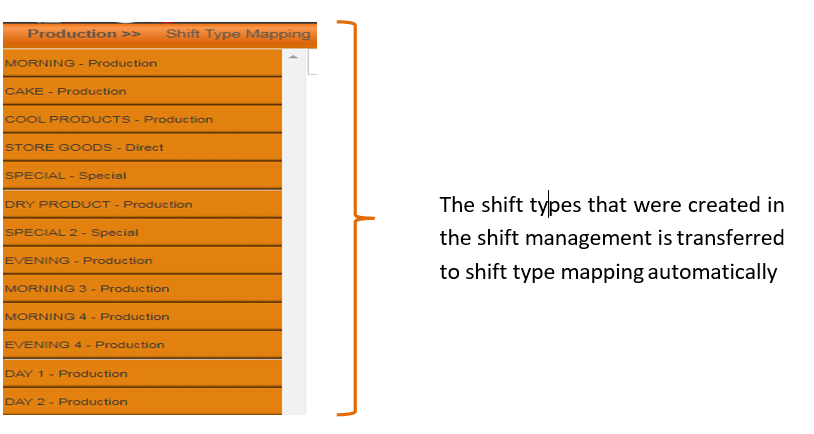

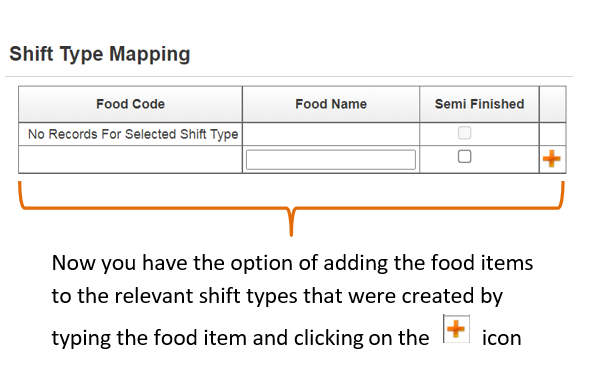

Before you start using the production module you need to create the shift types which your restaurant has. This could be created in the shift type management option.

You can type the name of the shift and allocate the material type whether it be a production, a direct etc.

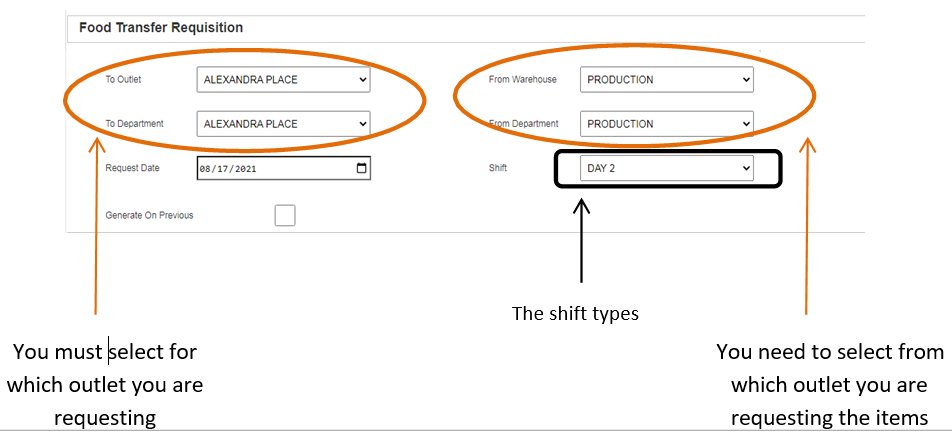

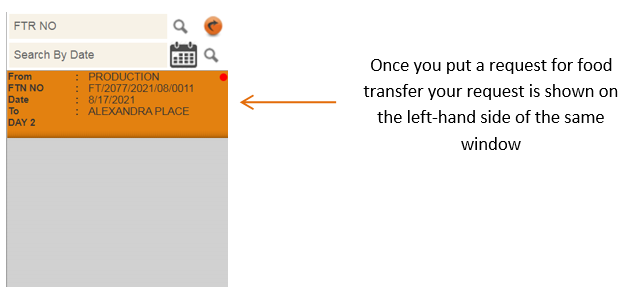

In the food transfer requisition option you have the option of requesting the needed food items through the system.

Once you have filled the relevant fields you get the option of typing the quantity for each food item

![]()

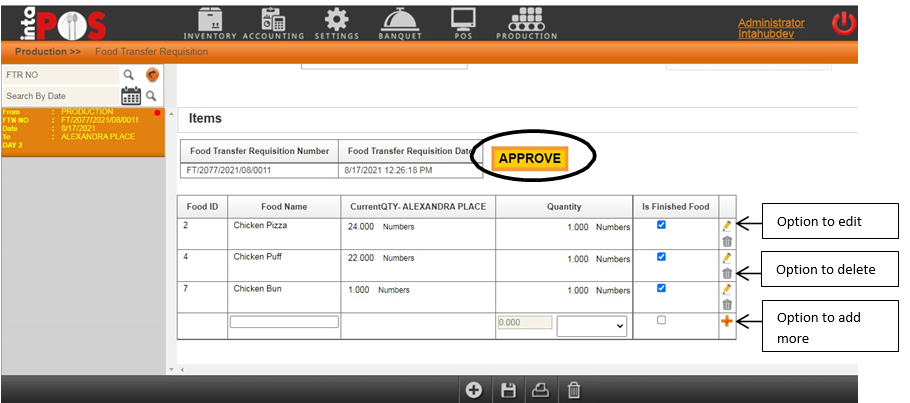

In the next step you need to approve this food transfer request. In order to do that you click on the request form as shown above and then you will get the option of approving it as shown below.

You can approve this request by clicking on the approve button highlighted above.

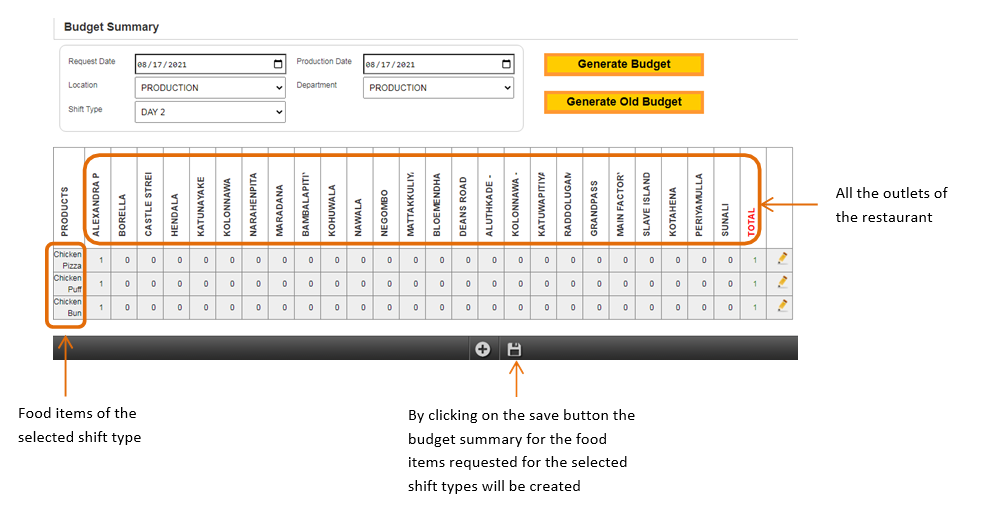

Once you have approved the food transfer requisition it is then moved to budget summary. In this step you have the option of seeing the total number of items requested from different outlets for the selected shift type by filtering the location and the shift type as shown below.

Once you have created the budget summary for these requested food items it is then moved to production plan automatically.

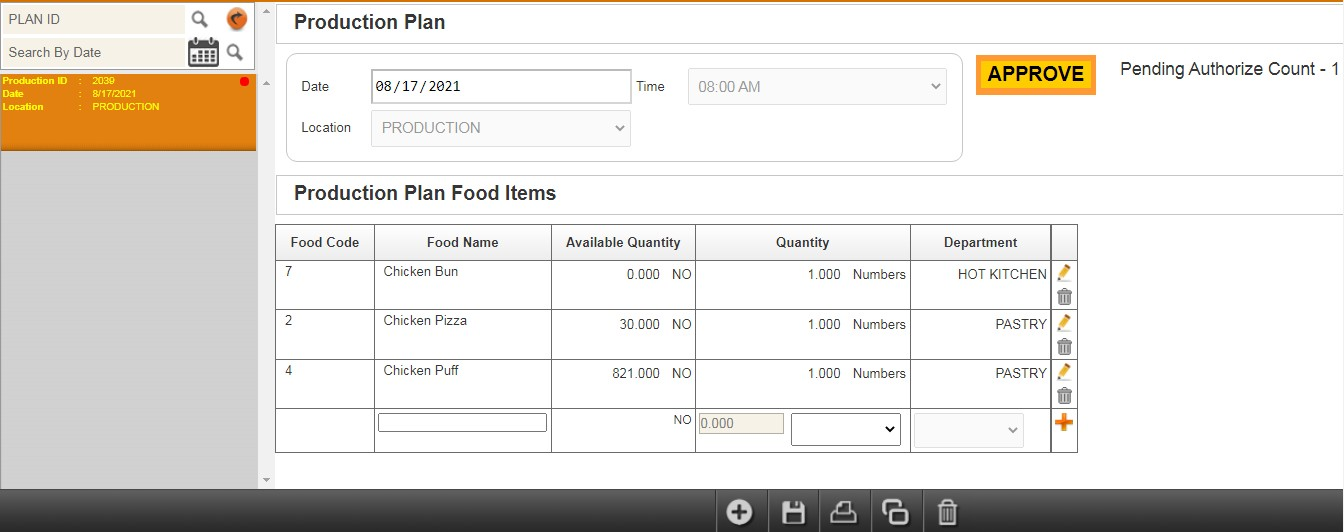

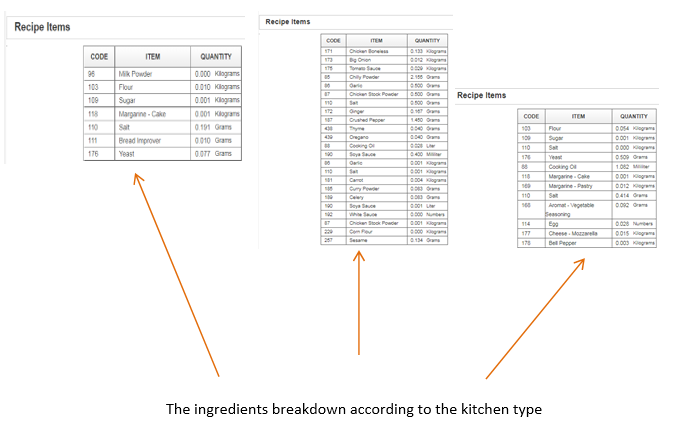

In the production plan, the food items that were requested is been categorized according to the kitchen types with the requested quantity. You need to approve the production plan as well in order to move to the next step. You can approve this production plan simply by clicking on the "Approve" button

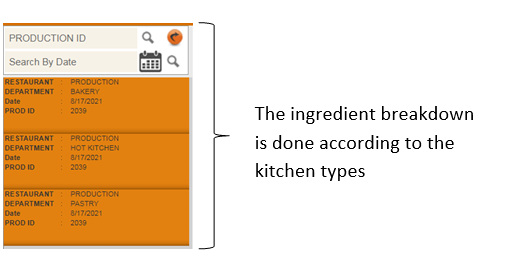

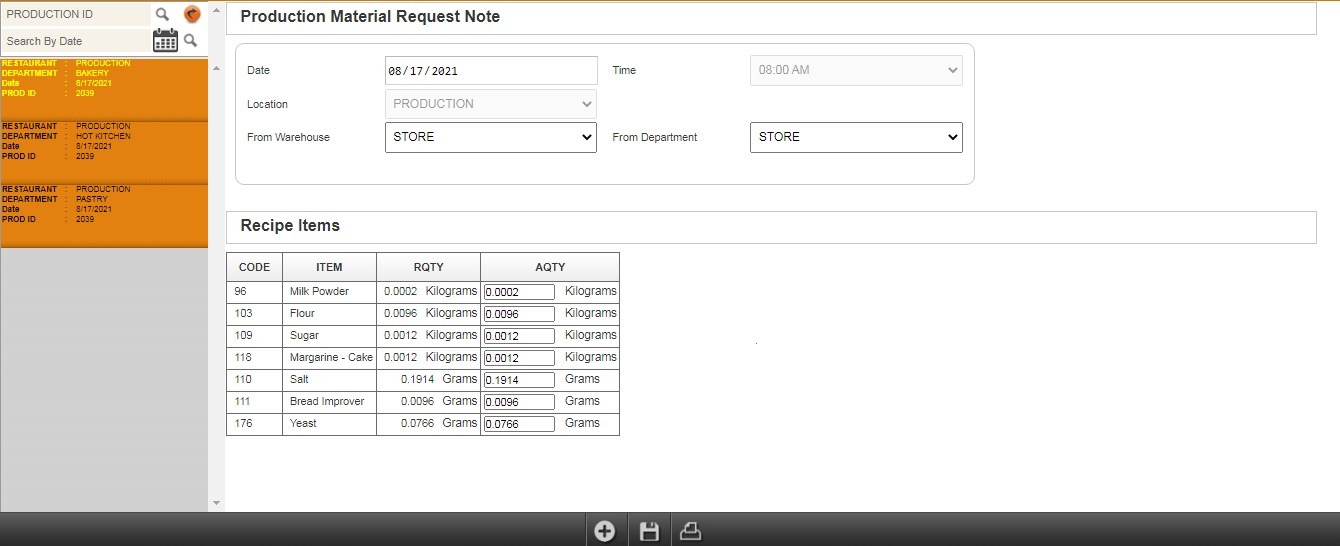

Up to now you have only been requesting and approving the requested food items. But in the Production Material Request Note you get a breakdown of all the ingredients used for these requested food items as shown below.

You then need to select them one by one and select as to from which warehouse you will be getting these ingredients and save them as shown below.

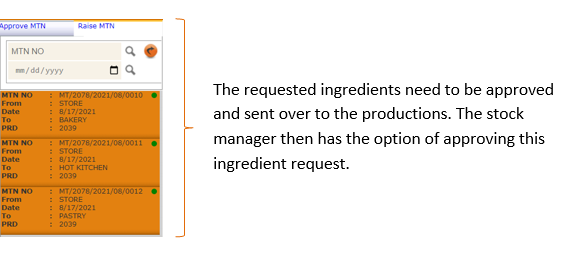

In order to make the food items that were requested the production requested for the ingredients from the stores. As it was requested from the stores that request is now been moved to the Material Transfer Note on the stock management in the inventory module

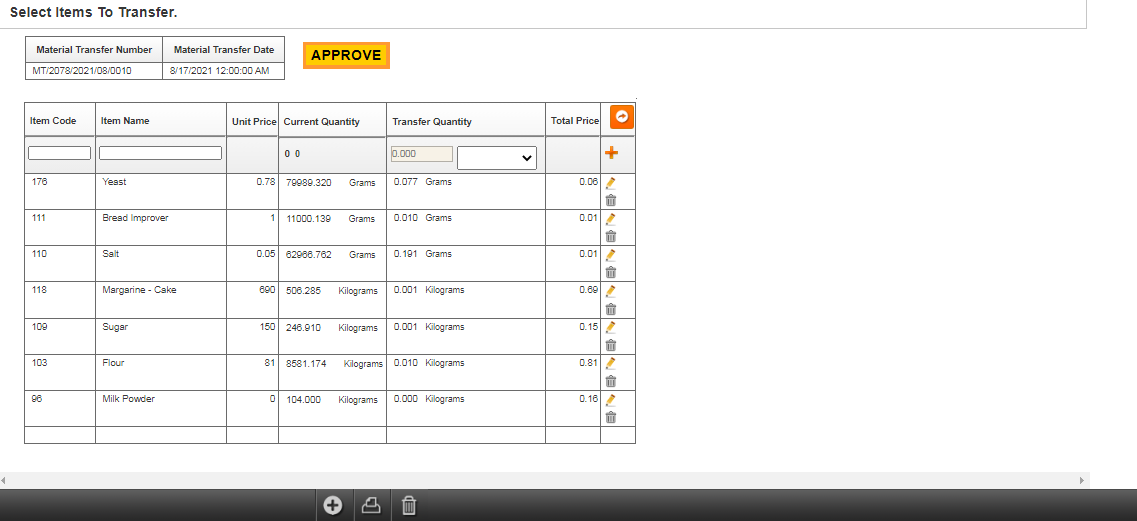

The ingredient request could be approved by selecting the requests one by one and by clicking on the "APPROVE" button.

In the final stage of approving this ingredient request the authorized person has the right to approve it, revert it or reject it.

He can do so by clicking one of the below icons

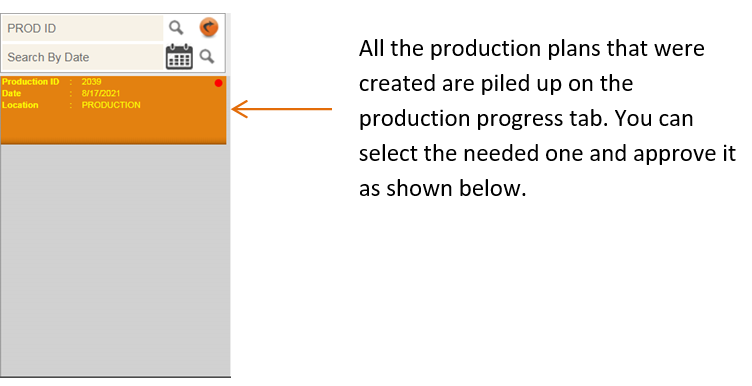

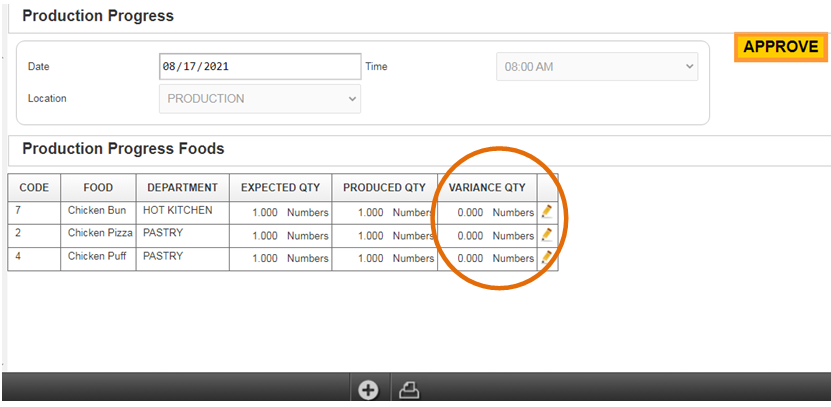

Once the ingredients are been sent over from the stores the production site can start making the requested food items. Once this process has started you have the option of viewing the progress of this production through production progress.

In this tab you have the option of editing. This is created in case the requested amount of food items are less than requested you can edit it. It then shows a variance if there is any in the variance tab.

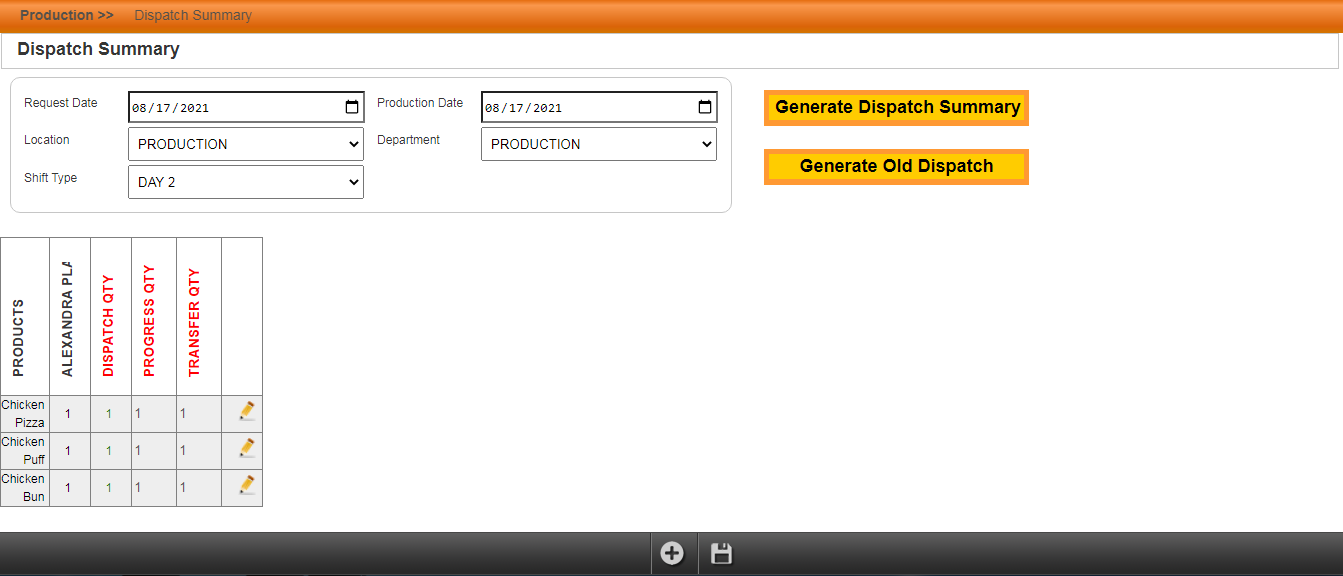

In the dispatch summary tab you get a summary of the total number of requested food item are to be dispatched outlet wise, the progress quantity which was updated in the production progress and we have transfer quantity as an added advantage to show how much exactly are been transferred.

In the dispatch summary tab you get a summary of the total number of requested food item are to be dispatched outlet wise, the progress quantity which was updated in the production progress and we have transfer quantity as an added advantage to show how much exactly are been transferred.

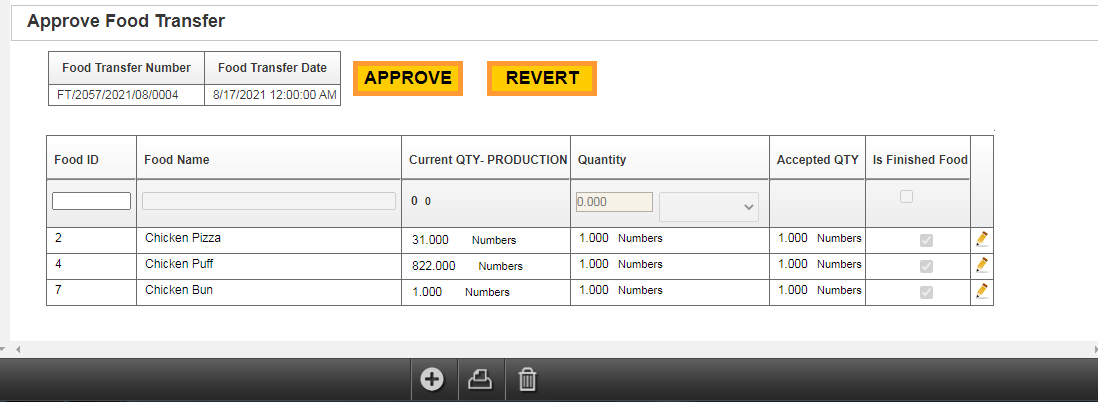

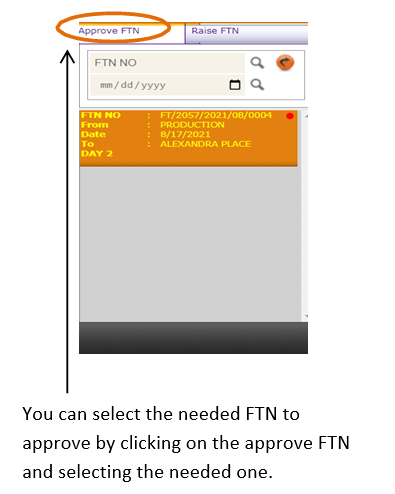

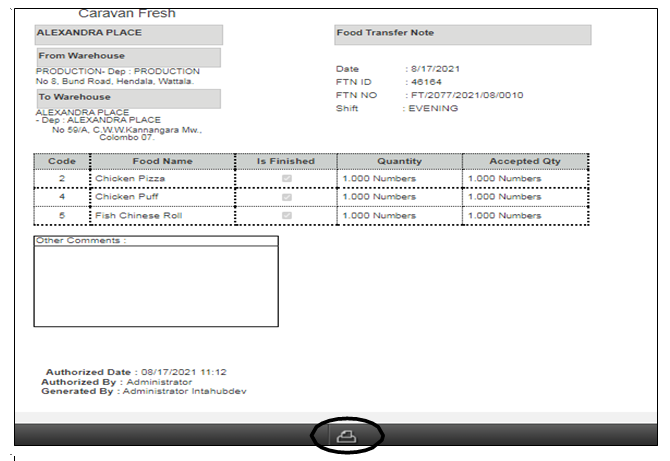

Once the whole production plan is completed the authorized person has the option of approving whether these food items were delivered to the relevant outlets or not. This could be done on the Food Transfer Note option. Here you have the option of either approving it or reverting it simply by clicking on the below shown icons.

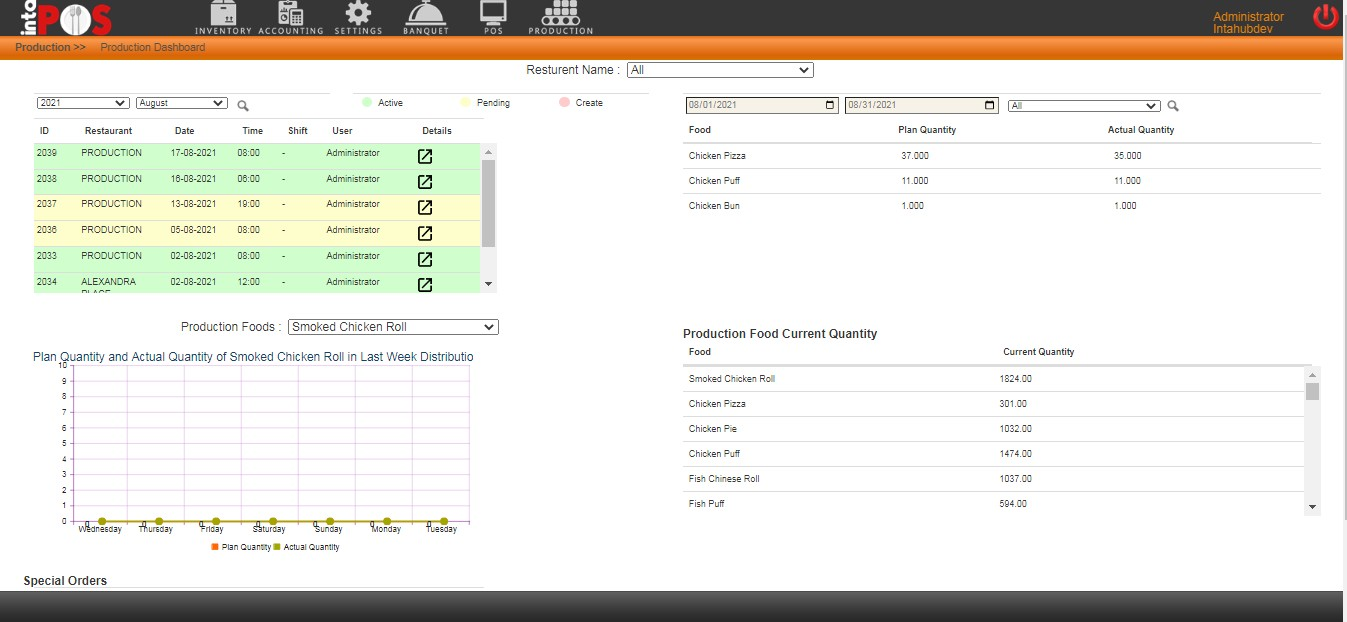

In the production dashboard you can view a summary of current quantity of the production food, daily and weekly distribution of plan quantity and actual quantity of food items etc. as shown below.

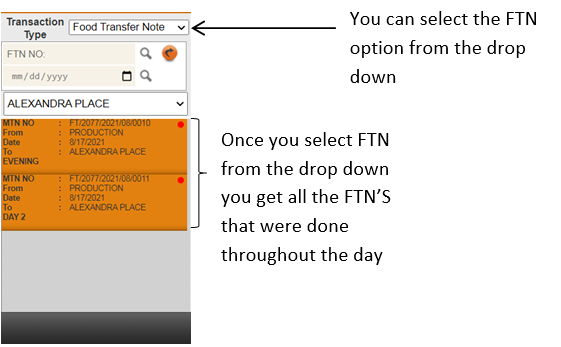

In the production transaction print you have the option of taking a print out of the Food Transfer Notes that were done.

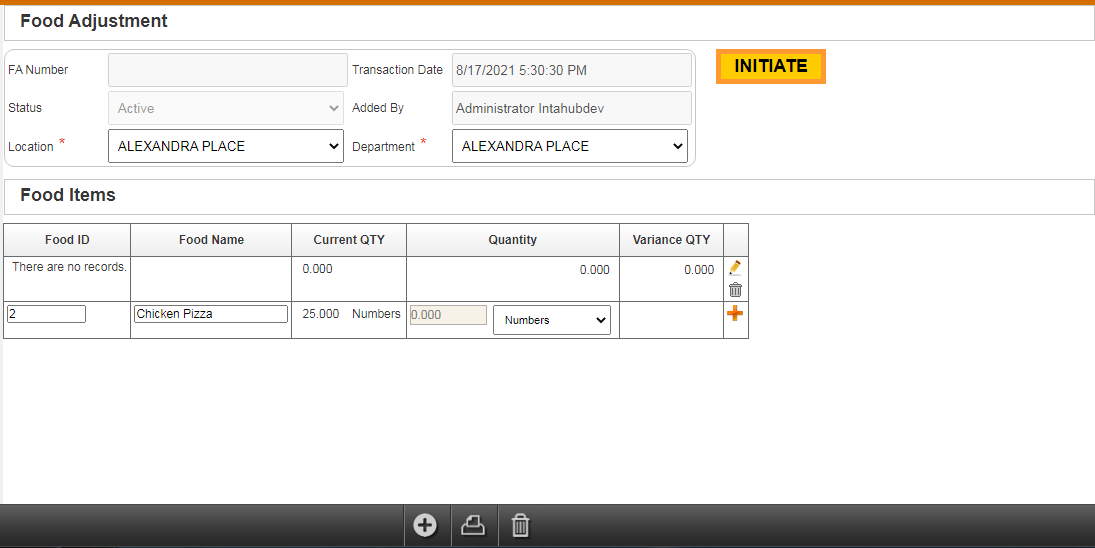

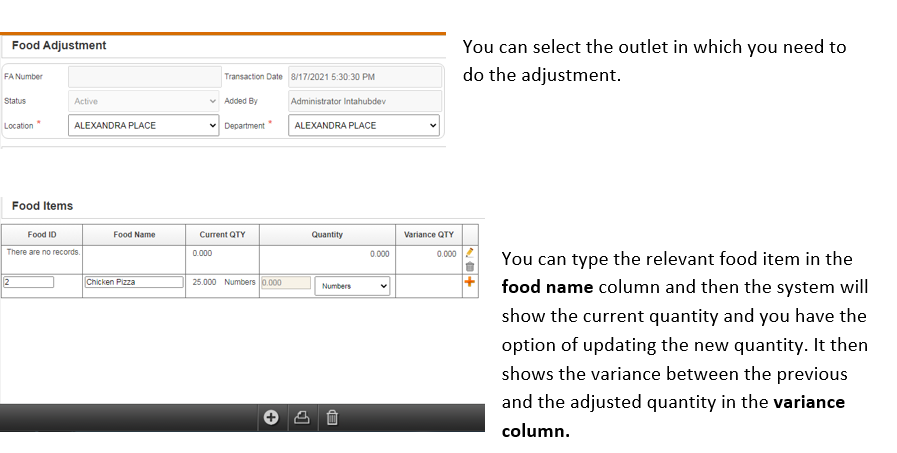

The food items that are configured to the system could be adjusted if needed. That could be done through the food adjustment option.

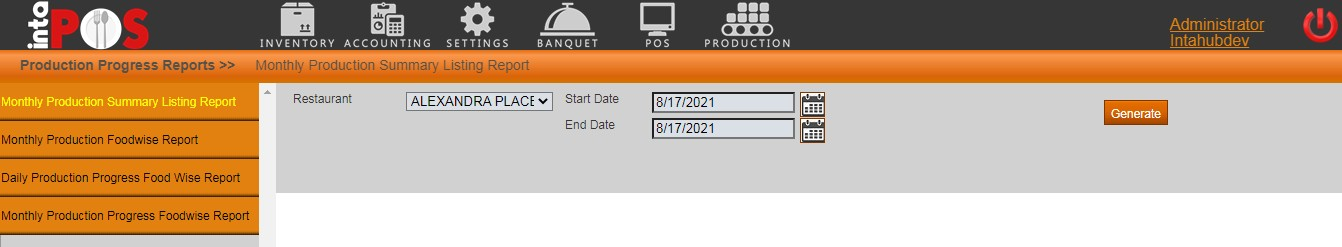

Reports on various transactions that were done in the system could be generated through production reports option. Our reports feature is divided into two parts, Production progress reports and Material Request reports

The above mentioned reports could be generated. You can select the types of report you wish to generate and filter the date range and the outlet for you to view the report.

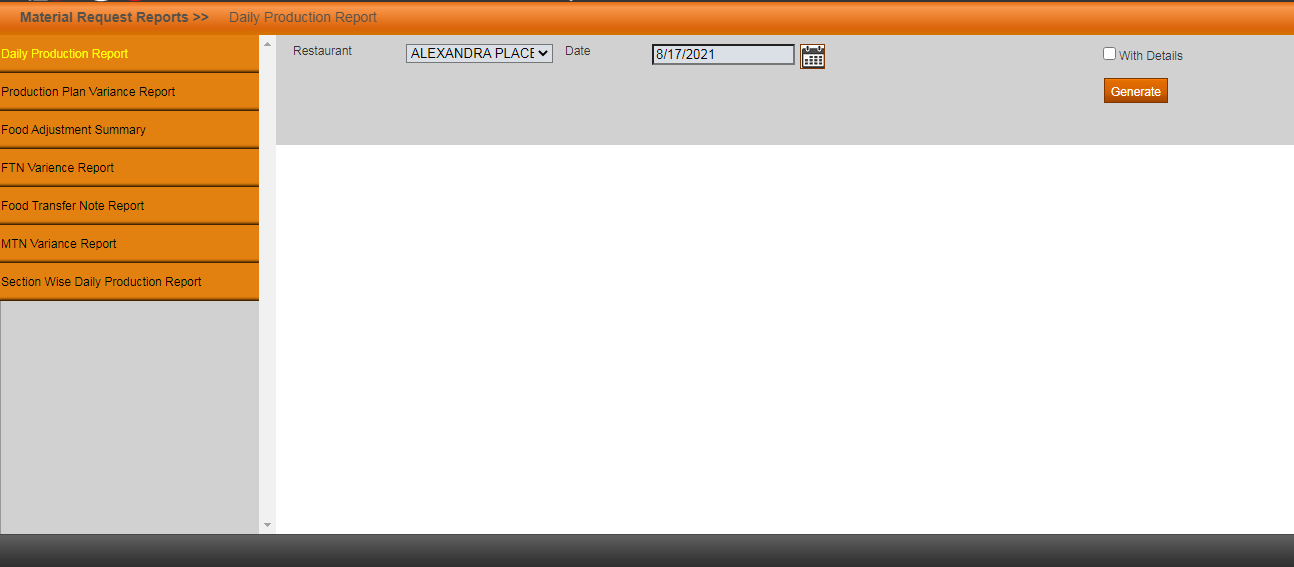

Reports on various transactions that were done in the system could be generated through production reports option. Our reports feature is divided into two parts, Production progress reports and Material Request reports

The above mentioned reports are available in the Material Request Reports

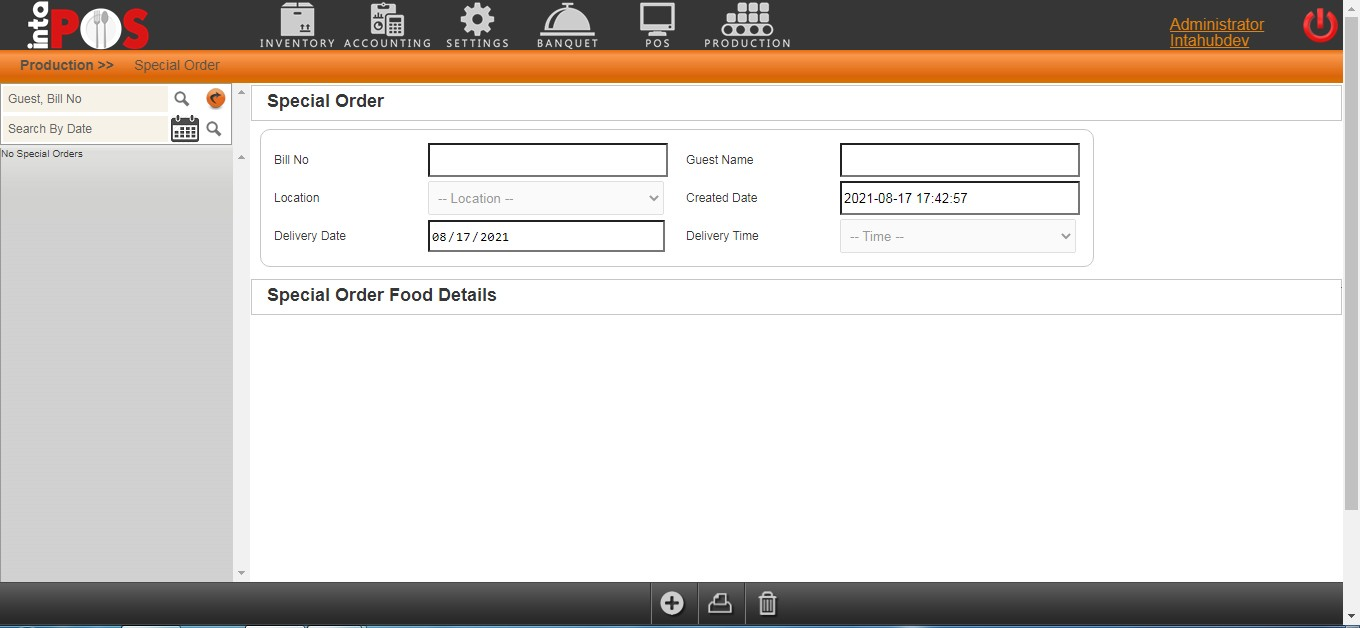

We have a special feature in our production system. As our systems are all integrated with each other you have the option of taking up special orders from the POS system. And every special order that is been created from the front end is added to the production module. The special orders could be viewed through special order option.