Mean: A purchase requisition is a formal document that is used when an employee needs to purchase or order something on behalf of their restaurant.

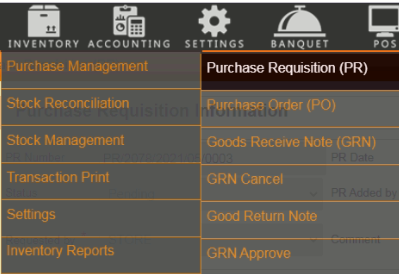

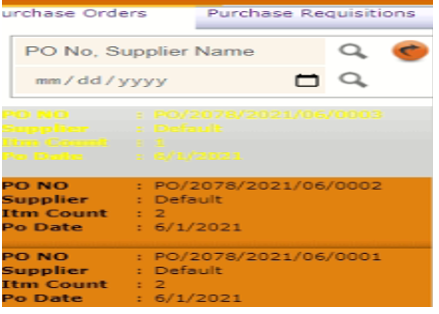

How to access PR? Purchase Requisition form

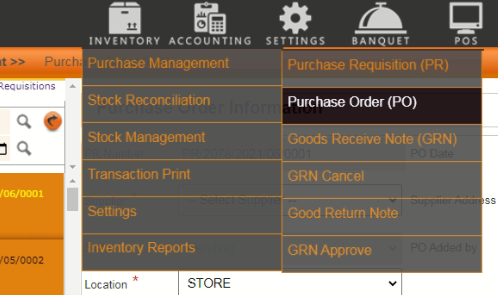

Access: In order to create a purchase requisition user needs to select Inventory, then purchase management and purchase requisition

Location: Dashboard >> Inventory>>Purchase Management>> Purchase Requisition

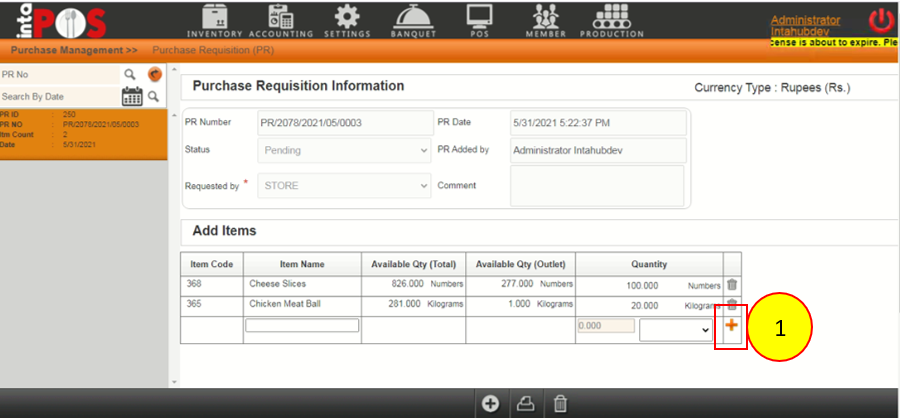

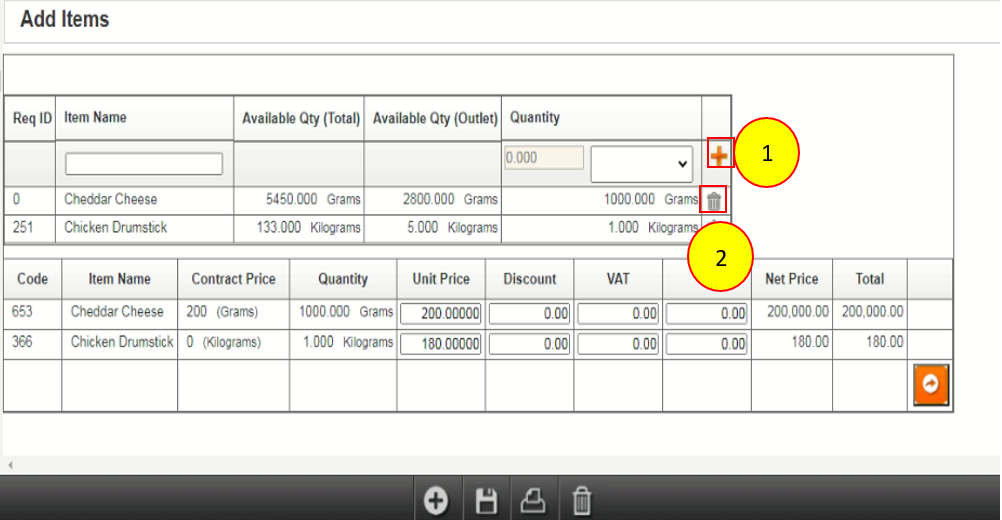

Fill all the required and item name press enter add quantity and select plus mark No.1 to add item to the table.

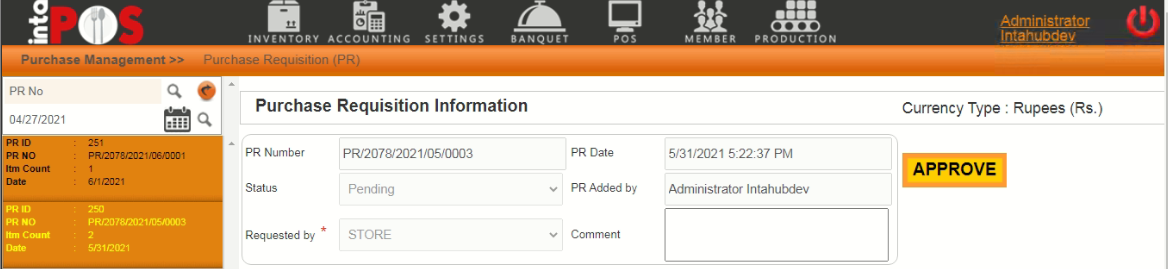

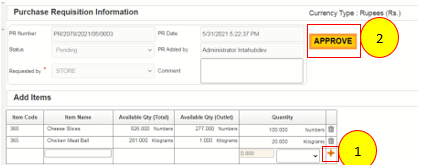

Mean: After making the purchase requisition the employee need to approve it or remove it or add more items to it.

Select the required PR. Select the plus button No.1 to add more items and approve button No.2 to approve the PR.

Access: In order to approve the purchase requisition user needs to select the created PR and then need to select the approve button.

Location: Dashboard >> Inventory>>Purchase Management>> Purchase Requisition>>Approve

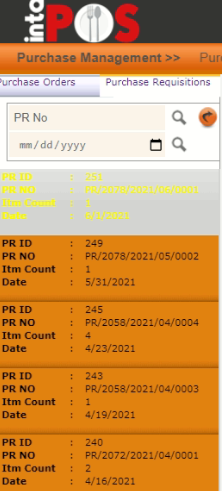

Mean:A purchase order is a commercial document and first official offer issued by a buyer to a seller indicating types, quantities, and agreed prices for food items.

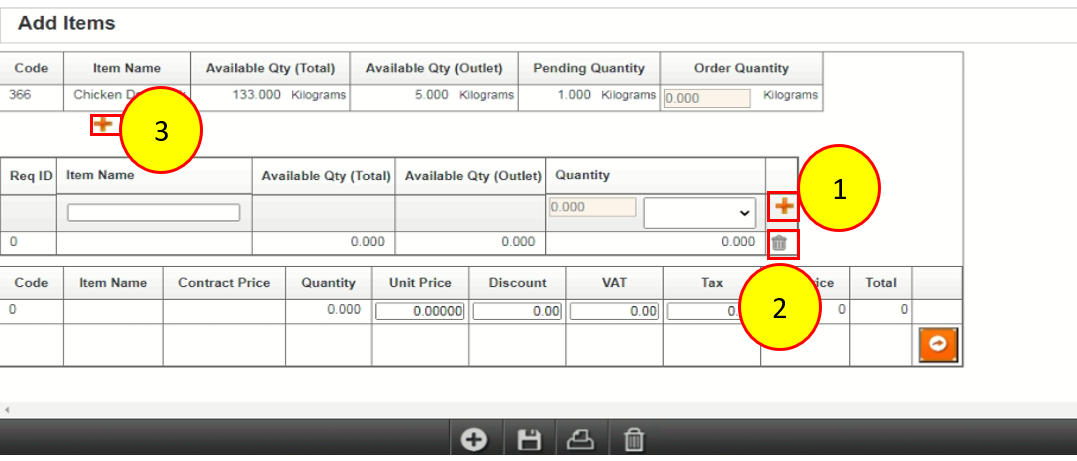

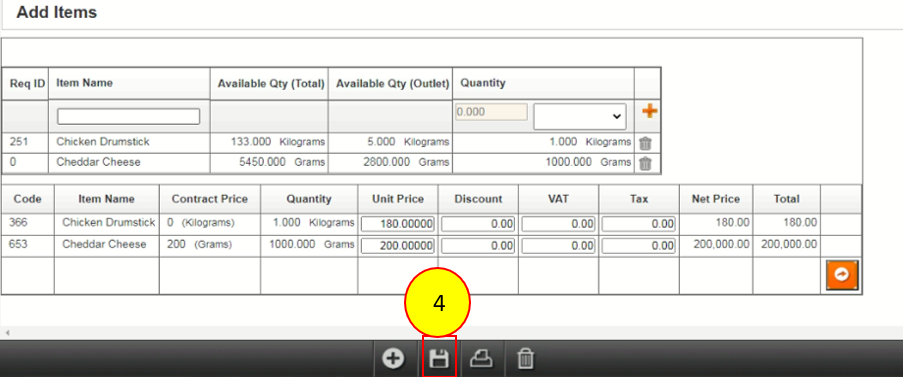

Access to Purchase Order Select the created purchase requisition. Select plus mark No.3 and add the PR to the PO Select save button No.4 to save the added items.

Access: In order to create the purchase order user needs to select the created PR and then need to do the required changes and save the purchase order.

Location: Dashboard >> Inventory >> Purchase Management >> Purchase Order

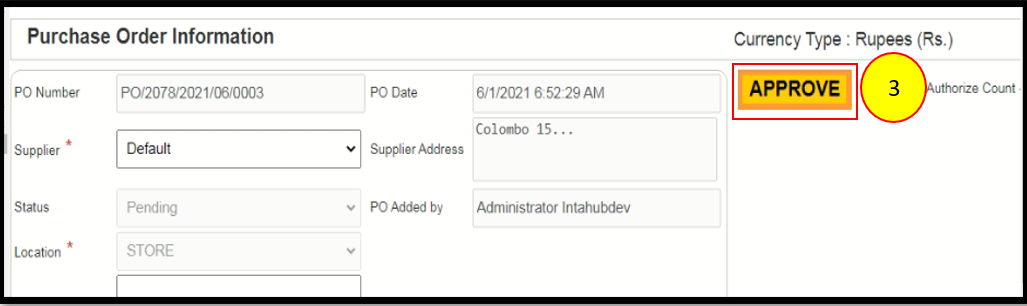

Mean:After creating purchase order employee needs to approve the purchase order.

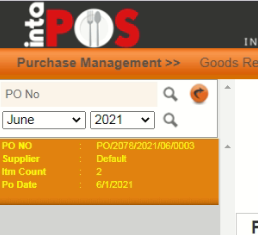

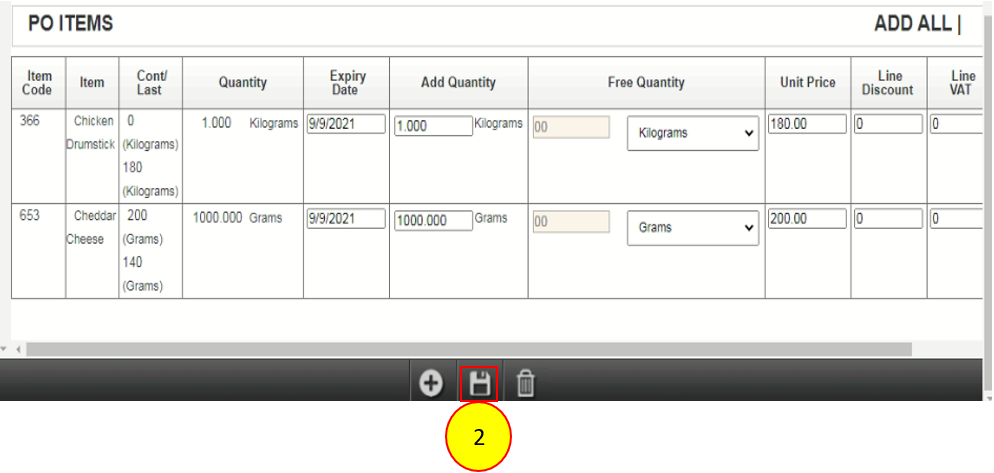

Select the GRN Select the PO Add quantities and free quantities to the PO items. Select save button No.2 to save the PO items.

Access: In order to approve the PO user needs to select the PO and then needs to select the approve button.

Location: Dashboard >> Inventory >>Purchase Management >> Purchase Order >> Approve PO

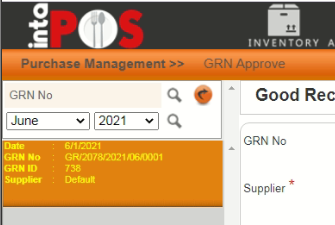

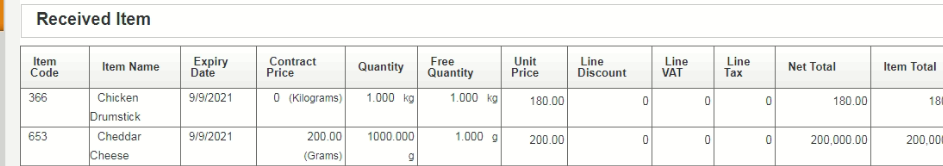

Mean:A goods receipt note (GRN) is created to record the delivery of items from your suppliers. A GRN is created against an issued purchase order.

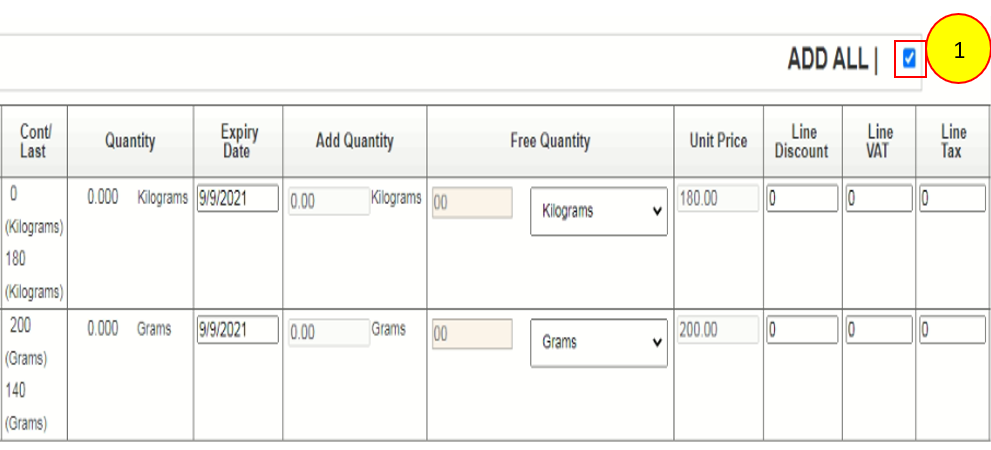

Select the PO Select add button No.1 and delete button No.2 to add and delete items before approve the PO Then Select the approve button to approve the PO

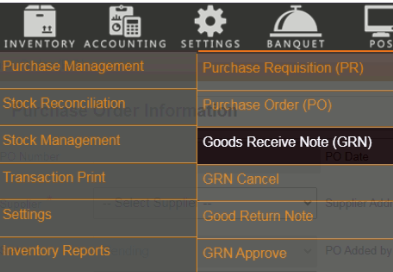

Access: In order to create the GRN user needs to select the Inventory then purchase management then the GRN

Location: Dashboard >> Inventory>>Purchase Management>> GRN

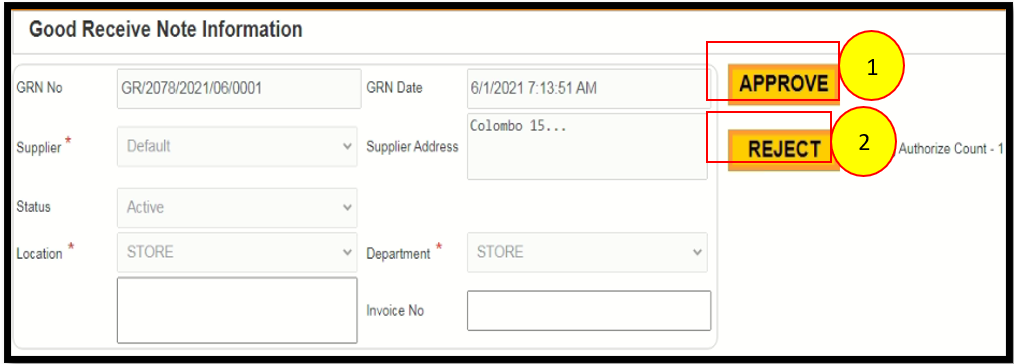

Mean:If the GRN is with the required quantities and items the authorized employee has to approve it.

Select the GRN Received items are loaded to the screen. Select approve button No.1 to approve the GRN.

Access: In order to approve the GRN user has to select the required GRN then only user can approve the GRN.

Location: Dashboard >> Inventory >> Purchase Management >> GRN >> Approve GRN.

If user needs to reject the GRN, user can select reject button No.2 GRN option.

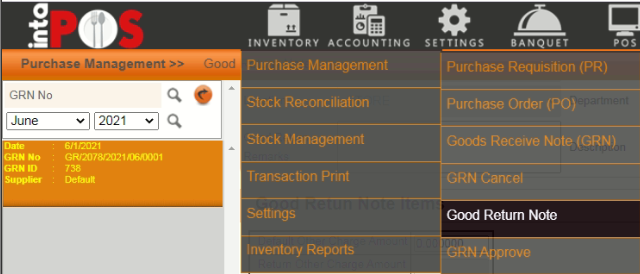

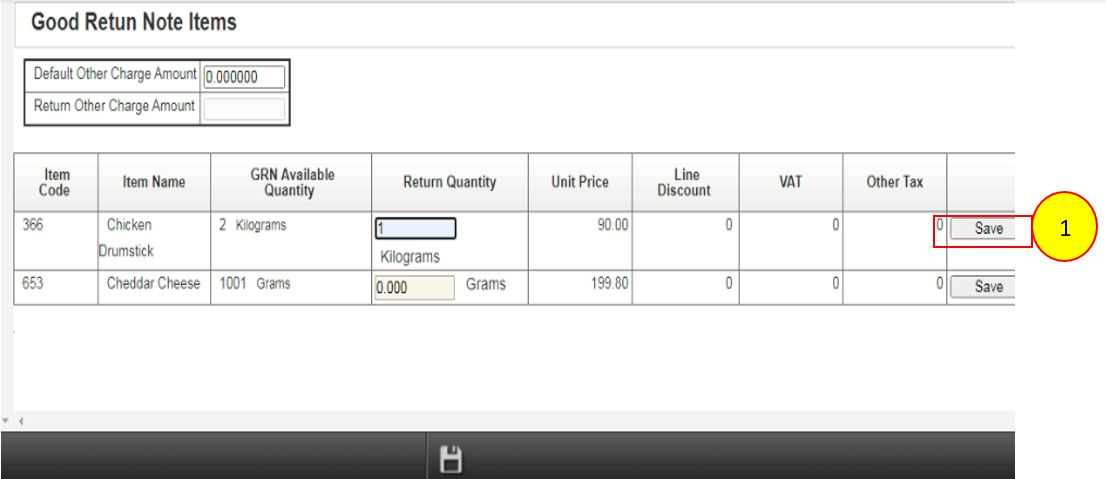

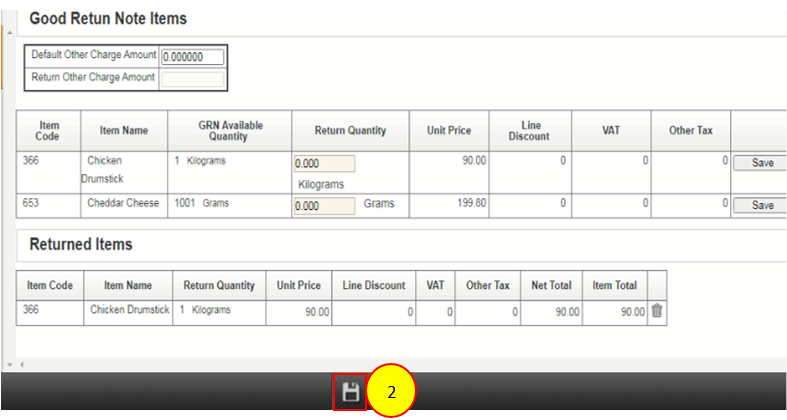

Mean: After creating goods receipt note (GRN) user can return the quantities or items using good return note

Select the good return note. Add the return quantity and select save option No.1. Entered return quantity will display on the table

Access: In order to create the good return note user needs to select the good receive note and add the return items and quantities to the good return note.

Location: Dashboard >> Inventory>>Purchase Management>> Good Return Note

And then select the save option No.2 to save the good return note

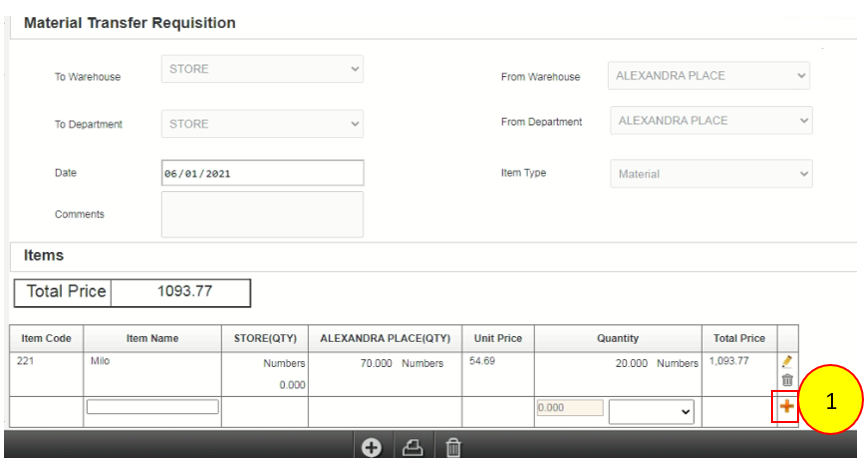

Mean: A materials transfer requisition form, or a material request, is a document used by the production department to request materials they need to complete a manufacturing process.

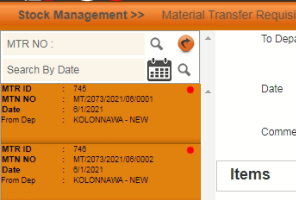

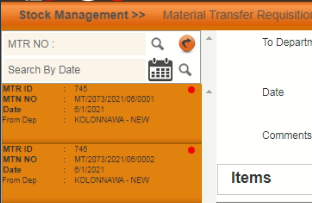

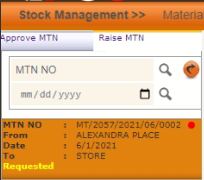

Select the material transfer requisition. Material transfer requisition User can select the created material transfer requisition from the below list. After selecting the material transfer requisition following table will display. Approved material transfer requisition will display with a green colored mark

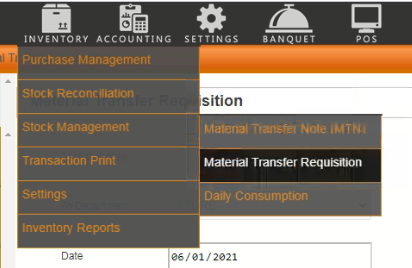

Access: In order to create material transfer requisition, user needs to access stock management and then material transfer requisition.

Location: Dashboard >> Inventory >>Stock Management>>Material Transfer Requisition

After entering the required item and the quantity user can select the plus button No.1 to add the item and edit button to edit the entered data and delete button to delete the entered data.

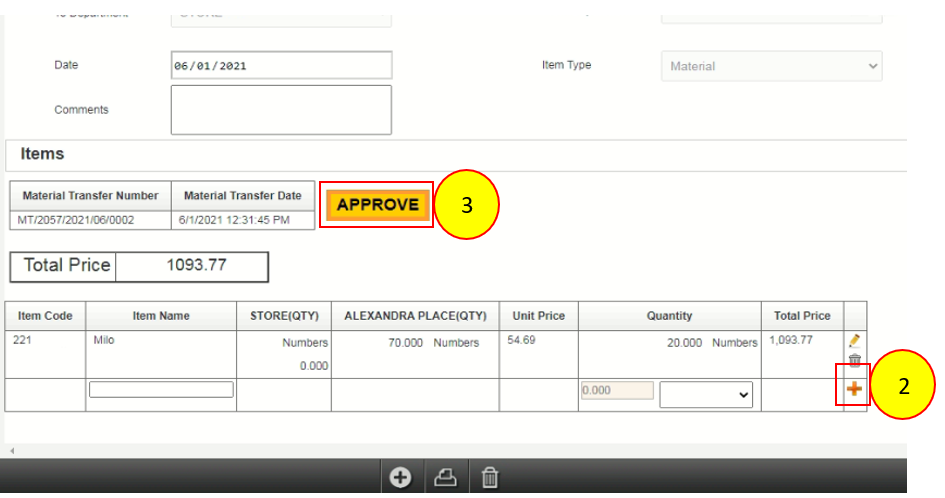

If the user needs to edit or delete the added item user can use edit delete option or else if user needs to add new item user can use plus button No.2 to add the item.

Finally, user can select the approve button No.3 to approve the changed material transfer requisition.

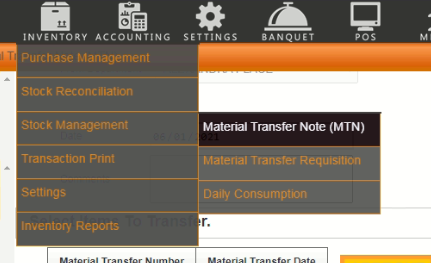

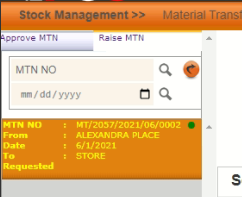

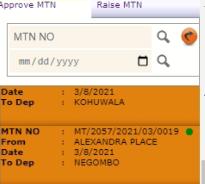

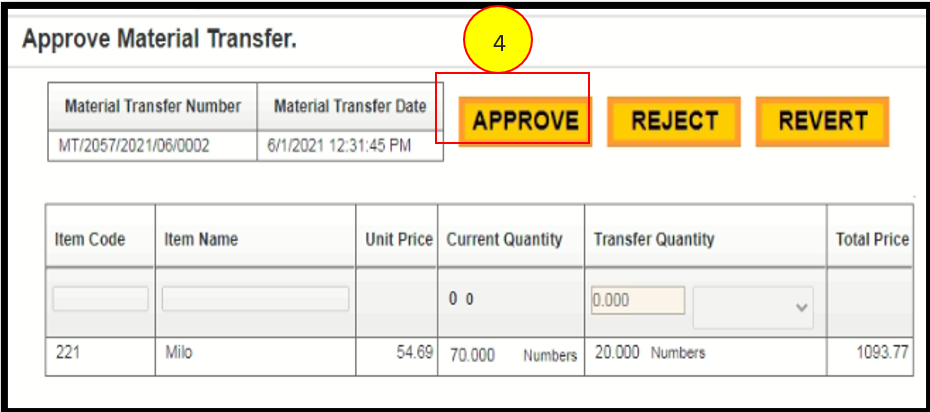

Mean: Material Transfer Note is a document used for transferring the material from one department to another department or one site to other site

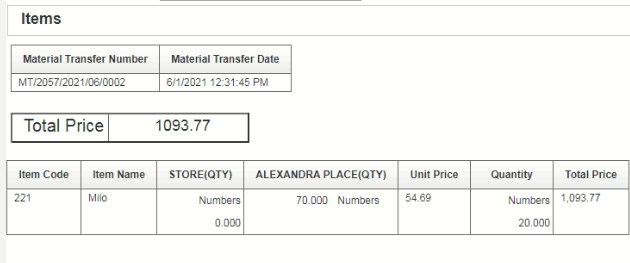

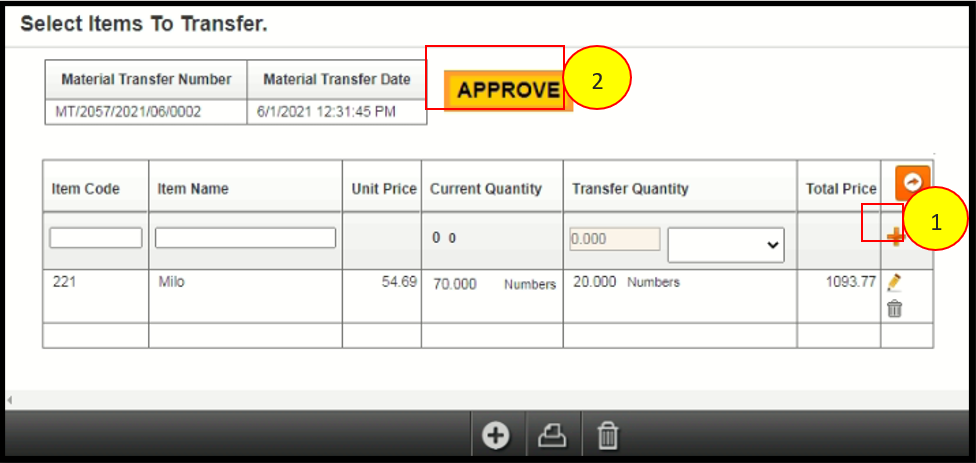

Select the Material transfer Note. Load the created material transfer requisition. Here user can enter new item using plus button No.1 and user can edit or delete the entered item using the edit and delete buttons.

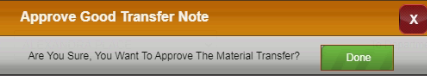

: After that following change will appear. Select the requested material transfer. Final approval of material transfer. Here user can select approve button No.3 to approve the final material transfer note or reject button to reject material transfer and revert button to revert the material transfer to the first step of apporoval. Success message of material transfer approval.

Access: In order to create material transfer note, user needs to access Inventory then stock management and finally Material Transfer Note (MTN).

Location: Dashboard >>Inventory >>Stock Management>>Material Transfer Requisition

Finally select the approve button No.2 to approve the transferred materials.

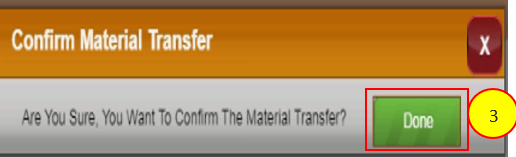

After select the approve button following message will pop up then user needs to select done button No.3 to confirm the material transfer.

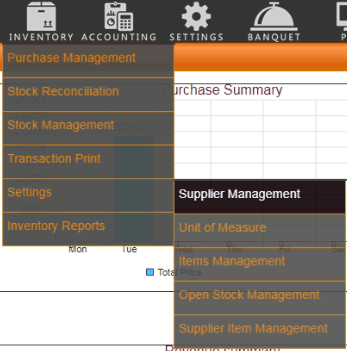

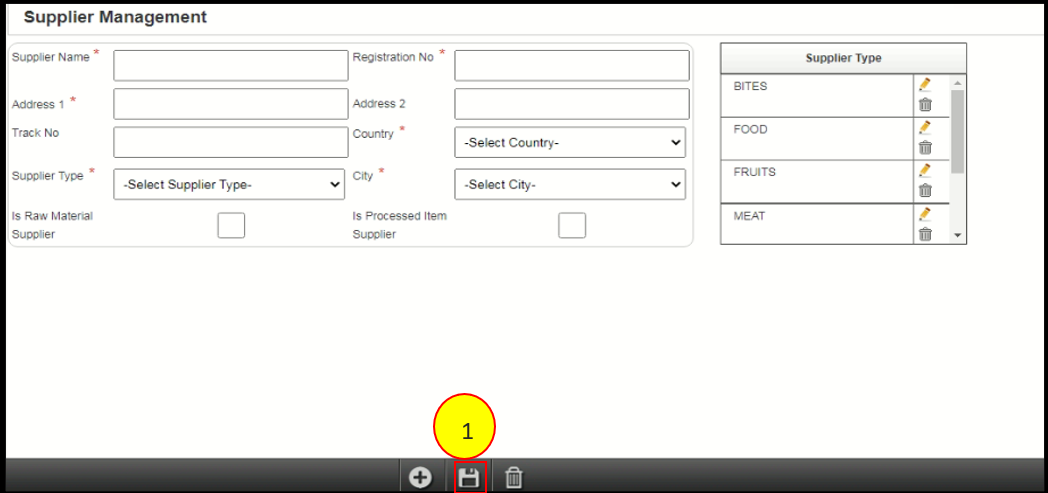

Mean: Here system supports to manage the raw material suppliers and processed item suppliers.

Select the supplier management. Enter all the required details and select save button to save the supplier.

Access: In order to access supplier management user needs to select inventory then select settings finally needs to select the supplier management.

Location: Dashboard >> Inventory >>Settings>>Supplier Management

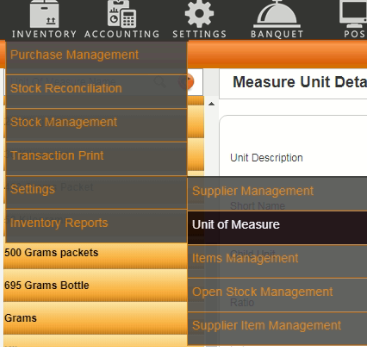

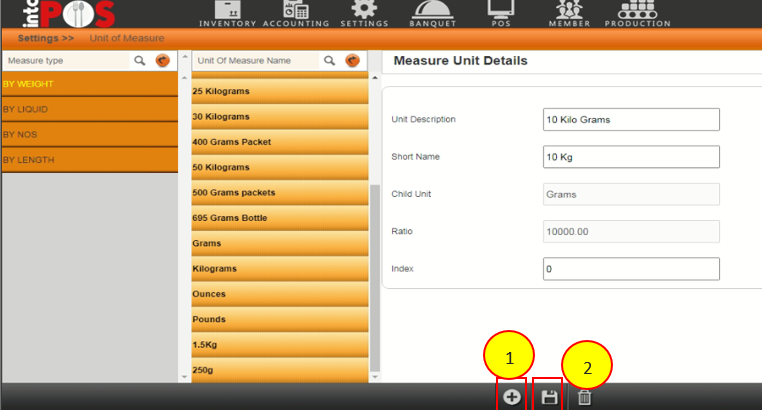

Mean:A unit of measurement is a definite magnitude of a physical quantity.

: Select the unit of measure. Select the measure type then select the plus button No.1 and add all of the required details and select the save button No.2.

Access: In order to access unit of measures user needs to access inventory and then settings then unit of measure.

Location: Dashboard >> Inventory >>Settings>>Unit of Measure

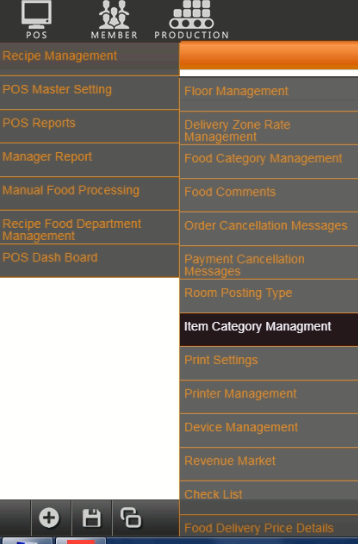

Mean: To manage the items properly user needs to create the types of the items and the category types.

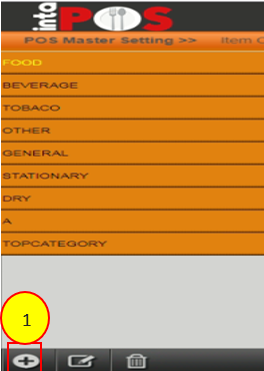

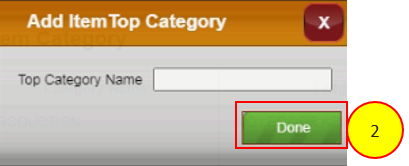

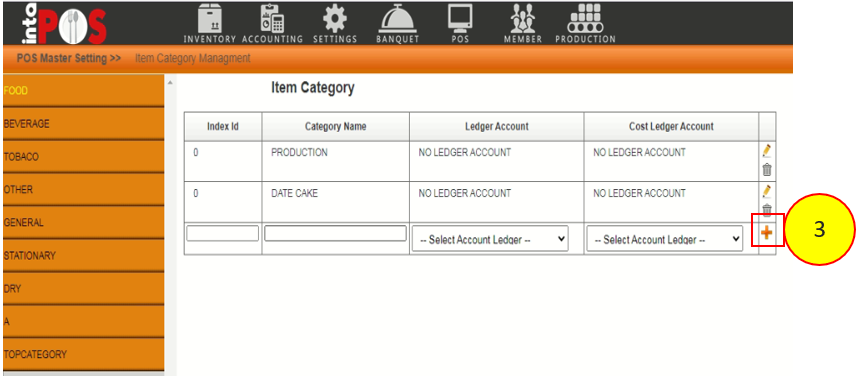

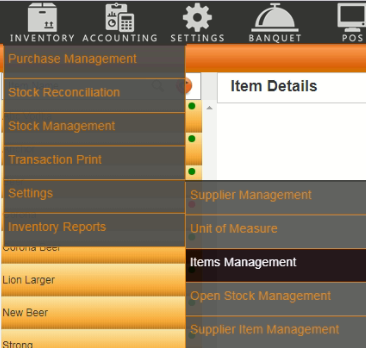

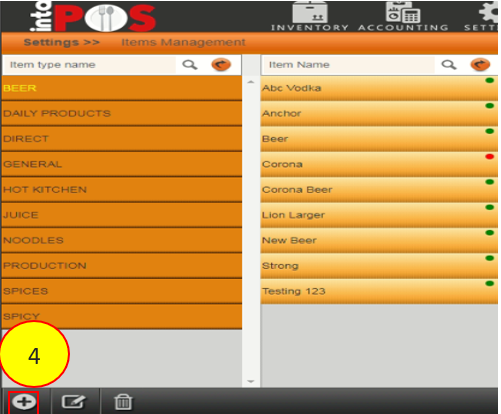

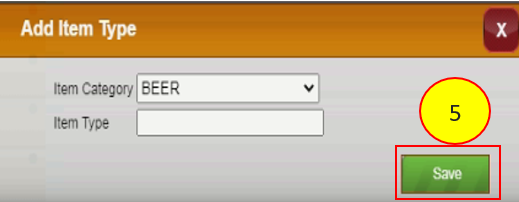

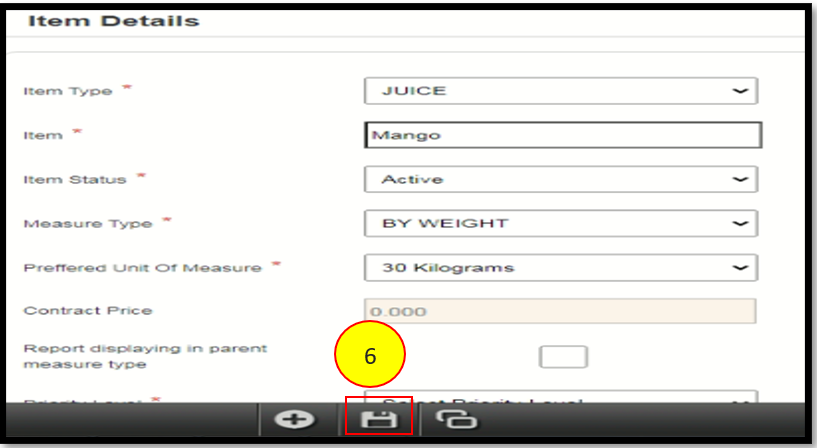

: How to access the item category management. Select the plus button No.1 and then following screenshot3 will display. Enter the top category of the required item and select done button No.2. :Select the top category from the list and add the item category under it. After entering all of the details select plus button No.3 to add details to the table.Select the items management. Then select the plus button to create the item type.Select the required item category and then create the item type under it. Then select the save button No.5.Select the created item and enter the details of the items. Enter save button No.6 to save the entered item.

Location: Dashboard >> POS >> POS Master Settings >>Item Category Management

Mean: Stock Reconciliation is the process of counting and evaluating the stock-in-property.

Access: In order to access stock reconciliation, select inventory then select stock reconciliation.

Location: Dashboard >> Inventory >>Stock Reconciliation >> Stock Adjustment